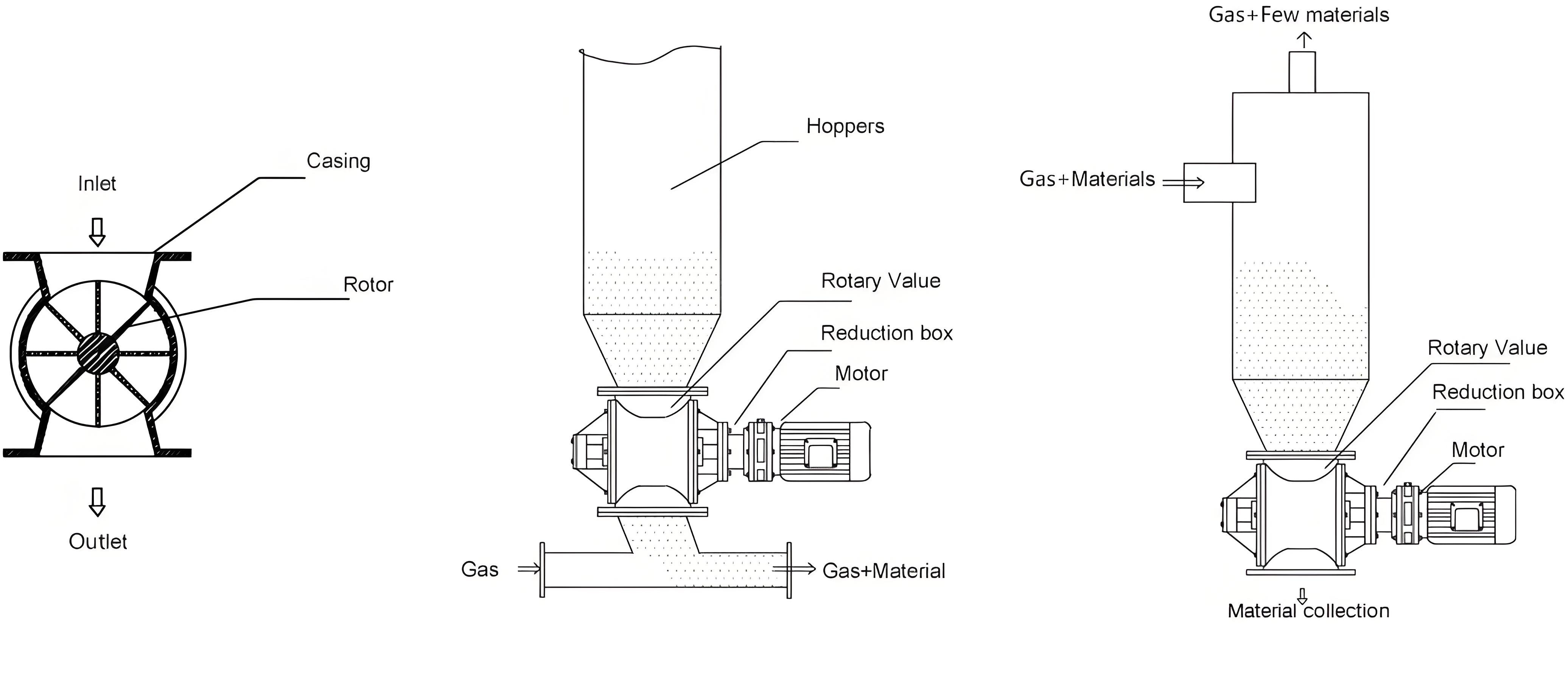

Rotary valves ( also known as rotary airlocks or rotary feeders ) are commonly used in industrial and agricultural applications as a component in a bulk or specialty material handing system. Rotary valves are primarily used for discharge of bulk solid material from hoppers/bins, receivers and cyclones into a pressure or vacuum-driven pneumatic conveying system. Components of a rotary valve include a rotor, shaft housing, head plates and packing seals and bearings. Rotors have large vanes cast or welded on and are typically driven by small internal combustion engines or electric motors.

Rotary valves have wide application in industry wherever dry free-flowing powers, granules, crystals or pellets are used. Typical materials including cement, ore, sugar, minerals, grains, plastics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, etc.

Symptom | Possible cause | Solution |

Rotor does not rotate | No power to motor | Check breaker Check motor heaters Check motor starter |

Wrong Connection type | Correct the connection type to “△” | |

Voltage or frequency much less than design | Improve power supply | |

Rotor is jammed | Inspect rotor and remove object | |

Chain is broken or has come off | Remove guard and inspect drive | |

Faulty motor or gear reducer | Remove chain and run motor with no load | |

Excessive noise | Bearings need grease | Grease bearing, replace if necessary |

Rotor has shifted | Inspect rotor and realign | |

Rotor is rubbing end housing | alignment clearance | |

Drive chain is rubbing on guard | Reposition chain guard or sprockets and chain | |

Excessive air leakage through airlock | Worn rotor wiper | Inspect and replace |

Motor burn, shaft break | Rotary valve too small | Change bigger valve |

Copyright © 2024 LEAD INDUSTRIAL ( CHANGZHOU ) CO., LTD. All Rights Reserved. XMLMAP